Contact us for a free no obligation quote…

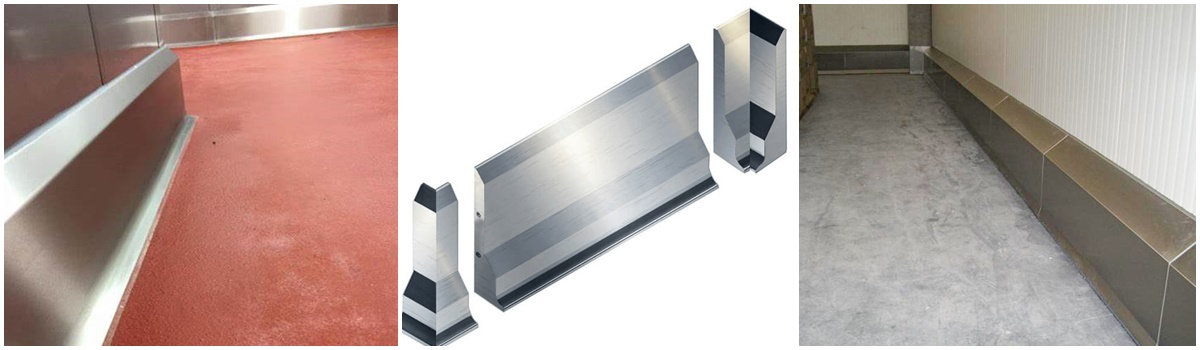

Fabrication and Welding of Stainless Steel Kerbing, UK

If you require industrial stainless steel kerbing for any project in the UK, give C&P Fabrications a call.

Stainless Steel Kerb protects walls and panels from impacts. Fabricating stainless steel kerbing involves several precise welding processes to ensure durability and corrosion resistance. Here’s an overview of the steps involved:

- Material Preparation:

- Design: Develop detailed designs and specifications for the kerbing.

- Cutting: Use tools like plasma cutters or laser cutters to cut stainless steel sheets or plates to the required dimensions.

- Welding Process:

- Cleaning: Clean the stainless steel surfaces to remove any contaminants that could affect the weld quality.

- Tack Welding: To hold the pieces in place, perform tack welds, which involve making small welds at key points.

- Full Welding: Complete the welds using one of the following methods:

- TIG Welding (Tungsten Inert Gas): Provides precise control and is ideal for thin materials. It produces high-quality, clean welds.

- MIG Welding (Metal Inert Gas): Suitable for thicker materials and offers a faster welding process.

- Stick Welding (Shielded Metal Arc Welding): Versatile and practical for outdoor work and thicker materials.

- Post-Weld Treatment:

- Grinding and Polishing: Smooth rough welds and edges using grinders and polishers.

- Passivation: Apply a passivation treatment to enhance the corrosion resistance of the stainless steel. This involves cleaning the surface with an acid solution to remove free iron and other contaminants.

- Quality Control:

- Inspection: Inspect the welds for defects or weak points. Non-destructive testing methods, such as dye-penetrant inspection or ultrasonic testing, can ensure weld integrity.

- Finishing:

- Coating or Painting: Apply a protective coating or paint if required, although stainless steel is often left uncoated due to its natural corrosion resistance.

These steps ensure the stainless steel kerbing is strong, durable, and corrosion-resistant, making it suitable for various applications.