Contact us for a free no obligation quote…

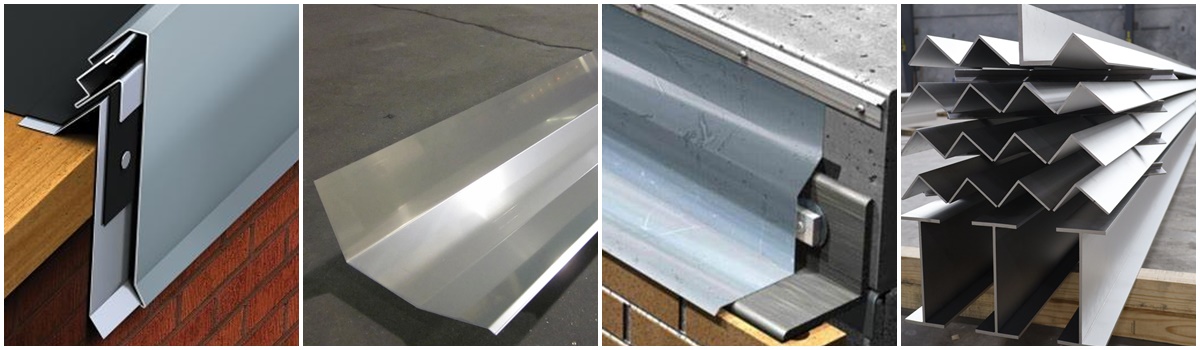

Fabrication of Steel & Aluminium Flashings, UK

If you require steel or aluminium flashings for any project in the UK, give C&P Fabrications a call.

Flashings and trims in steel or aluminium are designed to meet all internal and external requirements. Flashings and trims are mainly used to seal corners and edges of buildings, preventing water ingress. Gutters collect water from the roof and direct it to ground level or belowground drainage.

Flashings and trims, when produced in colours that contrast with the main building profile, can serve as architectural features in addition to their practical weatherproofing function.

Creating steel flashings involves several precise steps to ensure they are durable and effectively protect buildings from water ingress. Here’s an overview of the fabrication process:

-

- Design and Planning:

- Design: Develop detailed designs and specifications for the flashings, considering factors like dimensions, angles, and specific building requirements.

- Material Selection: Choose the appropriate type of steel, such as galvanized steel or stainless steel, based on the specific requirements.

- Cutting and Shaping:

- Cutting: Cut steel sheets to the required dimensions using tools like laser cutters, plasma cutters, or shears.

- Bending and Folding: Form the steel into the desired shapes using bending or folding techniques. This is crucial for creating the various profiles needed for different types of flashings, such as barge boards, abutment flashings, and parapet flashings.

- Surface Preparation:

- Cleaning: Clean the steel surfaces to remove any contaminants, rust, or mill scale that could affect the quality of the finished product.

- Assembly and Joining:

- Joining: Depending on the design, some flashings may require welding or riveting to join different sections. This ensures a strong and durable connection.

- Post-Processing:

- Grinding and Polishing: Smooth out any rough edges or welds using grinders and polishers to ensure a clean finish.

- Inspection: Inspect the flashings for any defects or weak points to ensure they meet quality standards.

- Finishing:

- Coating or Painting: Apply a protective coating or paint to prevent rust and enhance appearance. This step is crucial for outdoor durability.

- Packaging and Delivery:

- Packaging: Package the finished flashings carefully to prevent damage during transportation.

- Delivery: Transport the flashings to the construction site or customer location

- Design and Planning:

These steps ensure that the steel flashings are strong, durable, and suitable for various applications, including roofing, cladding, and architectural features