Contact us for a free no obligation quote…

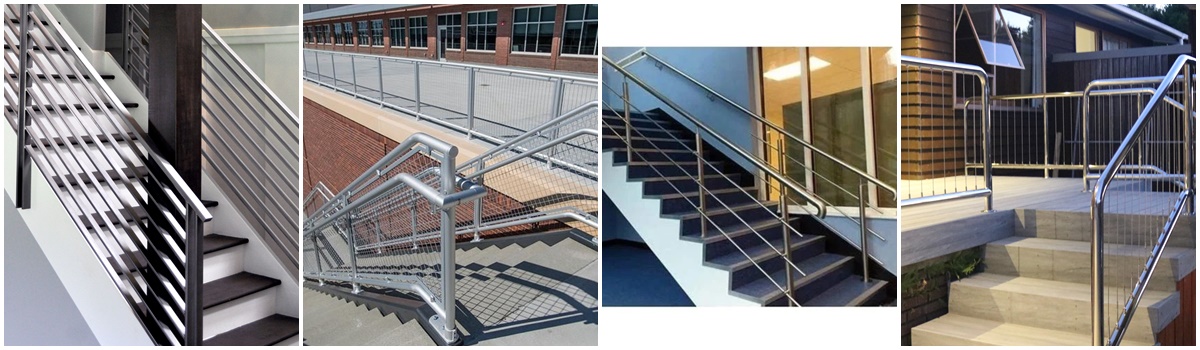

Fabrication & Welding for Steel Handrails, UK

If you require steel handrails for any project in the UK, give C&P Fabrications a call.

Steel fabrication for handrails involves several key steps to ensure functionality and aesthetics.

Material Selection: Common materials include mild steel, carbon steel, stainless steel, aluminium, and galvanised steel. The choice depends on the specific requirements, such as durability, appearance, and environmental conditions.

Creating steel handrails involves several precise steps to ensure they are durable, safe, and aesthetically pleasing. Here’s an overview of the fabrication process:

- Design and Material Preparation:

- Design: Develop detailed designs and specifications for the handrails, considering factors like dimensions, load-bearing capacity, and style.

- Cutting: Use tools like laser cutters, plasma cutters, or saws to cut steel sheets, plates, or tubes to the required dimensions.

- Forming and Shaping:

- Bending and Rolling: Bend or roll the steel into the desired shapes. This is crucial for creating the curved or angled sections of the handrails.

- Punching, Stamping, and Notching: Use mechanical punching or stamping machines to create holes and notches for assembly.

- Surface Preparation:

- Cleaning: Clean the steel surfaces to remove any contaminants, rust, or mill scale that could affect the weld quality.

- Welding Process:

- Tack Welding: To hold the pieces in place, perform tack welds, which involve making small welds at key points.

- Full Welding: Complete the welds using one of the following methods:

- MIG Welding (Metal Inert Gas): Suitable for thicker materials and offers a faster welding process.

- TIG Welding (Tungsten Inert Gas): Provides precise control and is ideal for thin materials.

- Stick Welding (Shielded Metal Arc Welding): Versatile and effective for outdoor work and thicker materials.

- Assembly:

- Frame Assembly: Weld the main frame of the handrail, ensuring all joints are secure and aligned.

- Component Installation: As per the design, weld or bolt on additional components such as brackets, mounts, and supports.

- Post-Weld Treatment:

- Grinding and Polishing: Use grinders and polishers to smooth out rough welds and edges and ensure a clean finish.

- Inspection: Inspect the welds for defects or weak points. Non-destructive testing methods, such as dye-penetrant inspection or ultrasonic testing, can ensure weld integrity.

- Finishing:

- Coating or Painting: Apply a protective coating or paint to prevent rust and enhance appearance. This step is crucial for outdoor durability.

These steps ensure that the steel handrails are strong, durable, and suitable for various residential, commercial, and industrial applications.